Guangdong Taolin Plastic Co., Ltd. is a professional enterprise that produces PETG thick walled, thick bottomed, and highly transparent plastic bottles; Guangdong Taolin has imported one-step injection and blow molding integrated machines and mold equipment; Multiple injection and blowing integrated machines, multiple production workshops; You can choose from a hundred sets of mold bottle shapes. Food grade dust-free workshops and environmentally friendly raw materials implement full process data tracking from raw materials to production waste, and the fully automatic and fully inspected assembly line system is the foundation of product quality; The company has professional equipment, professional technology, and a management team that strives for excellence, committed to achieving perfection, equality, respect, mutual trust, and win-win cooperation in the enterprise.

Taolin Plastic currently has more than ten business managers and sales coordinators, specializing in business development in the cosmetics industry.

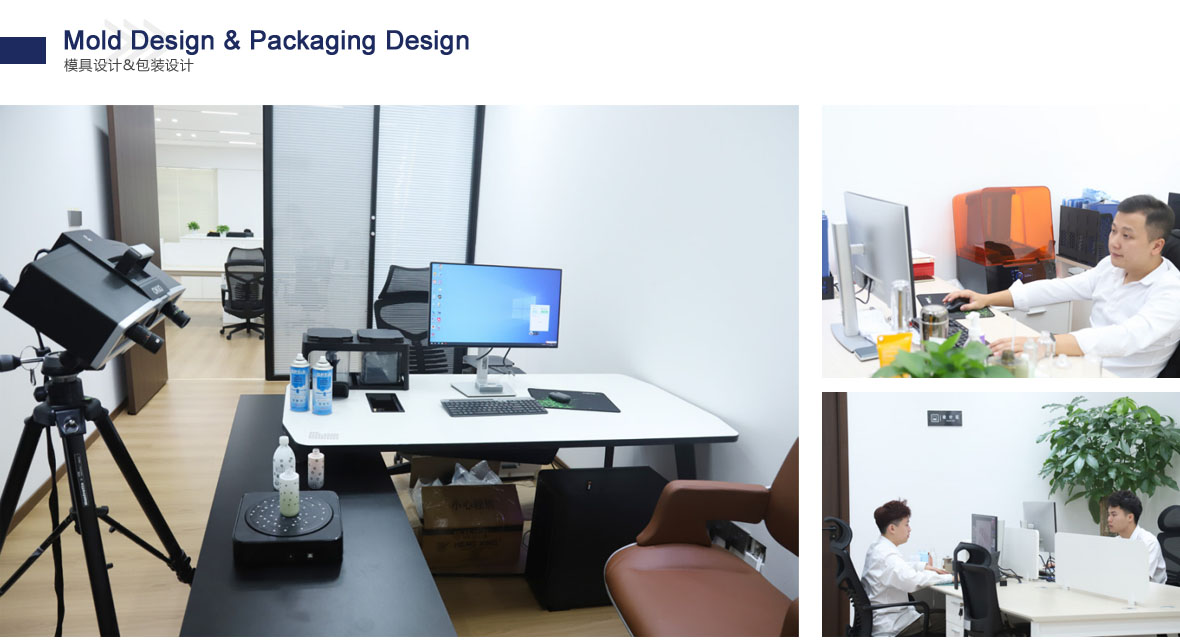

Design team: We have our own cosmetics packaging industry design and multiple designers in the field of appearance design and structure.

3D scanning instrument: fast scanning function, accelerates the process of mold design and product design. High precision and resolution, suitable for scanning product details.

Taolin Plastic currently has over a hundred independently developed skincare and washing products, with ISO9001 quality system certification and GMPC certification.

Taolin Plastic has multiple imported ASB one-step fully automatic blow molding equipment, integrated injection and blowing production, with higher product quality stability, efficiency, and cost-effectiveness. We also have multiple dust-free production workshops to provide customers with more comprehensive product services.

Taolin Plastic has multiple injection molding equipment and independently develops and produces lids for skincare containers, making the products more compatible and improving production efficiency.

Taolin Plastic Mold Workshop currently has hundreds of sets of bottle molds, providing customers with one-stop production services.

Taolin Plastic has multiple robotic arm devices that can accurately grasp, improve efficiency, and reduce adverse effects and microorganisms caused by human contact, resulting in higher surface cleanliness.

Taolin Plastic has multiple capping machines, and the assembly and quality inspection of various product covers are completed in one production line.

Taolin Plastic has a fully servo rotary screen printing machine, which can easily solve multi-color printing problems with precise positioning, high efficiency, and stable quality.

The quality department organizes the inspection of raw materials and outsourced products, supervises quality control during the production process, and handles various abnormal situations. After professional inspection by instruments, the product quality is ensured.

Raw material storage area, including ABS, PETG, polypropylene PP raw materials, etc.

Finished product storage area, daily inbound and outbound.